Cherry picker safety is crucial for protecting workers during aerial operations․ Standard Operating Procedures (SOPs) ensure safe practices, proper training, and adherence to regulations, minimizing accident risks effectively․

1․1 Understanding the Purpose of a Cherry Picker SOP

A Cherry Picker SOP outlines safe operating procedures to protect workers from injuries and ensure compliance with safety standards․ It serves as a training tool, detailing hazard identification, PPE requirements, and emergency protocols․ The SOP aligns with regulations like AS45001:2018, providing a structured approach to risk management and safe equipment operation․

1․2 Importance of Training and Certification

Training and certification are vital for safe cherry picker operation․ Operators must undergo accredited courses, such as IPAF’s PAL Card program, to understand hazards, equipment functionality, and emergency procedures․ Certification ensures competence, reduces accident risks, and meets legal requirements․ Employers must verify operators’ qualifications before allowing equipment use, ensuring a safe working environment․

Essential Safety Tips for Operating a Cherry Picker

Safe operation requires wearing PPE, observing weight limits, and using controlled movements․ Always maintain situational awareness and be prepared for emergencies to prevent accidents․

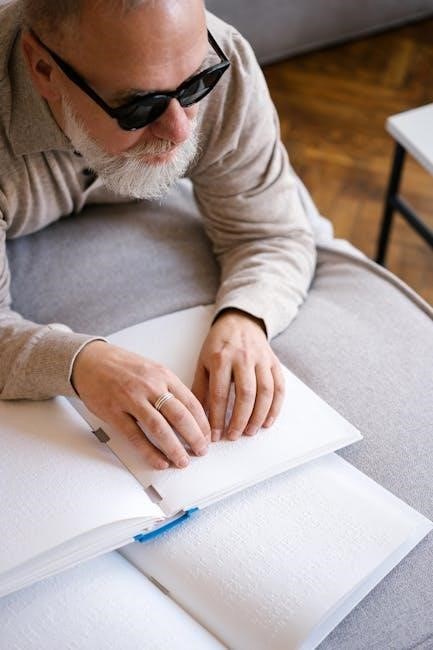

2․1 Wearing Personal Protective Equipment (PPE)

Wearing PPE is essential for cherry picker safety․ Operators should wear a hard hat, safety glasses, and a full-body harness with a securely anchored lanyard․ This protects against falls and falling objects․ Ensure all PPE is properly fitted and meets safety standards․ Additional gear like steel-toe boots may be required depending on the work environment․ Always follow manufacturer and safety guidelines for PPE use․

2․2 Observing Weight Limits and Load Restrictions

Always adhere to the cherry picker’s weight and load limits to ensure stability and safety․ Exceeding these can cause tipping or equipment failure․ Check the manufacturer’s guidelines for maximum capacity and avoid overloading the platform; Properly distribute the load and avoid reaching beyond the platform’s edge․ Compliance with these limits is critical to preventing accidents and maintaining operational safety․

2․3 Controlled Ascent and Descent Techniques

Use controlled movements when ascending or descending with a cherry picker to maintain stability․ Avoid sudden jerks or rapid speed changes, as they can destabilize the machine․ Ensure the platform is evenly loaded and clear of obstructions․ Always follow the manufacturer’s guidelines for safe operating speeds and monitor the surroundings during vertical movements to prevent accidents and ensure a smooth operation․

Pre-Operational Checks and Training

Thorough pre-operational checks and accredited training are essential for safe cherry picker use․ Ensure operators are certified and inspect equipment daily to prevent hazards and ensure compliance with safety standards․

3․1 Accredited Training Courses and Certification

Accredited training courses, such as those offered by IPAF, are vital for cherry picker operators․ These programs provide theoretical and practical knowledge, ensuring operators understand safety protocols, emergency procedures, and equipment functionality․ Certification, like the PAL Card, verifies competence and is legally required for operating cherry pickers safely and effectively in various work environments․

3․2 Conducting a Thorough Pre-Use Inspection

A pre-use inspection is essential to ensure the cherry picker’s safe operation․ Operators must check controls, tires, hydraulic systems, and safety features․ Any damage or malfunction should be reported and repaired before use․ This step helps prevent accidents and ensures the equipment functions correctly, providing a secure working environment for operators and bystanders alike․

3․4 Understanding Manufacturer Guidelines

Manufacturer guidelines provide detailed instructions for safe cherry picker operation․ These include control functions, maintenance requirements, and specific safety protocols․ Operators must thoroughly review and adhere to these guidelines to ensure compliance and prevent accidents․ Understanding the unique specifications of each model is crucial for optimal performance and safety, as outlined in the manufacturer’s manual․

Safe Operating Practices

Safe operation involves choosing stable surfaces, avoiding sharp turns, and maintaining situational awareness; Adhering to manufacturer guidelines ensures optimal performance and minimizes risks during cherry picker use․

4․1 Choosing a Stable and Level Surface

Always position cherry pickers on stable, level ground to prevent tipping․ Avoid soft or uneven terrain, especially in windy conditions․ Ensure the surface can support the machine’s weight and load․ Uneven ground can destabilize the equipment, increasing accident risks․ Use manufacturer-recommended stabilizing tools if necessary․ Regularly inspect the ground before operation to ensure safety and optimal machine performance․

4․2 Avoiding Sudden Movements and Sharp Turns

Sudden movements or sharp turns can destabilize cherry pickers, increasing the risk of tipping․ Operators should maneuver slowly and cautiously, especially when changing direction․ Adhere to recommended speed limits and avoid abrupt adjustments․ Sharp turns can shift the machine’s center of gravity, endangering both the operator and nearby personnel․ Always maintain control and situational awareness to ensure safe operation and prevent accidents․ Proper training emphasizes smooth, deliberate movements․

4․3 Maintaining Situational Awareness

Maintaining situational awareness is critical when operating a cherry picker․ Operators must continuously monitor their surroundings, including overhead obstacles, ground conditions, and nearby personnel․ Stay vigilant for potential hazards like power lines, uneven terrain, and weather changes․ Clear communication with ground personnel ensures coordination and safety․ Avoid distractions and always anticipate possible risks to prevent accidents and ensure smooth operations․ Situational awareness is key to safe and efficient cherry picker use․

Emergency Preparedness

Emergency preparedness is vital for safe cherry picker operation․ Operators must know how to use emergency stop buttons and respond to equipment failures․ Regular drills ensure readiness for unexpected situations, minimizing risks and ensuring quick, effective responses to potential hazards․

5․1 Understanding Emergency Stop Buttons

Emergency stop buttons are critical safety features on cherry pickers․ Operators must locate and test these buttons before use to ensure functionality․ In case of an emergency, pressing the stop button immediately halts the machine, preventing further risks․ Regular checks of emergency systems are essential to maintain worker safety and comply with safety regulations․ This ensures quick response capabilities during operational emergencies․

5․2 Responding to Equipment Failures

Knowing how to respond to equipment failures is vital for safe cherry picker operation․ If a malfunction occurs, remain calm and assess the situation․ Evacuate the platform if possible, then secure the machine to prevent movement․ Notify supervisors immediately and avoid attempting repairs without proper training․ Always follow manufacturer guidelines for emergency procedures to ensure safety and minimize risks during equipment failures․

Environmental and Site-Specific Factors

Assessing environmental conditions is critical for safe cherry picker use․ Evaluate ground stability, avoid overhead hazards, and monitor weather conditions to ensure safe operations in varying environments․

6․1 Assessing Ground Conditions

Ensuring the ground is stable and level is vital for cherry picker safety․ Soft or uneven surfaces can cause tipping, leading to accidents․ Always choose firm, flat ground and avoid slopes or wet areas․ Conduct a thorough site assessment before deployment to identify potential hazards and ensure the machine remains stable during operation, preventing risks to operators and bystanders․

6․2 Avoiding Overhead Hazards

Avoiding overhead hazards is critical when operating a cherry picker․ Identify obstacles like power lines, tree branches, and buildings to prevent collisions․ Maintain a safe distance, at least 9 meters from power lines, to avoid electrocution․ Use equipment with height sensors or consult a spotter to ensure clearance․ Plan the route carefully to minimize risks and ensure smooth operation without endangering personnel or equipment․

6․3 Managing Weather Conditions

Managing weather conditions is essential for safe cherry picker operation․ Avoid use during strong winds, heavy rain, or lightning, as these increase instability and hazard risks․ Ensure the machine is secured when not in use․ Monitor weather forecasts and halt operations if conditions deteriorate․ Extreme cold or heat may affect equipment performance, so follow manufacturer guidelines for operation in adverse weather to maintain safety and efficiency․

Maintenance and Servicing

Regular maintenance ensures cherry picker safety․ Daily inspections, hydraulic checks, and adherence to manufacturer guidelines prevent equipment failure and extend machine lifespan․

7․1 Regular Maintenance Requirements

Regular maintenance is essential for cherry picker safety and functionality․ Daily inspections should include checking hydraulic systems, controls, and tires․ Lubricate moving parts and ensure all functions operate smoothly․ Adhere to manufacturer schedules for detailed servicing, including oil changes and filter replacements․ Address any wear or damage promptly to prevent breakdowns․ Proper maintenance ensures optimal performance and minimizes risks during operation, safeguarding both equipment and operators effectively․

7․2 Importance of Hydraulic and Control System Checks

Hydraulic and control systems are critical for cherry picker operation․ Regular checks ensure smooth functionality and prevent sudden malfunctions․ Inspect hydraulic lines for leaks and damage, and verify that all control mechanisms are responsive․ Proper functioning of these systems is vital for safe ascent, descent, and maneuvering․ Addressing issues promptly avoids equipment failure, ensuring operator safety and maintaining reliable performance during elevated tasks․

Legal and Regulatory Compliance

Compliance with OSHA and IPAF regulations is essential for safe cherry picker operation․ Employers must ensure operators are trained and certified to meet legal standards and avoid penalties․

8․1 Understanding OSHA and IPAF Regulations

OSHA and IPAF regulations provide frameworks for safe cherry picker operations․ OSHA mandates training and certification for operators, while IPAF emphasizes equipment inspections and proper usage․ Adhering to these standards ensures compliance, reduces workplace risks, and prevents legal penalties․ Employers must stay updated on regulatory changes to maintain a safe working environment and protect employees from potential hazards associated with aerial lifts․

8․2 Ensuring Compliance with Safety Standards

Compliance with safety standards is vital for safe cherry picker operations․ Regular inspections, documented maintenance, and operator training ensure adherence to regulations․ Employers must verify certifications and maintain records․ Compliance protects workers, prevents incidents, and avoids legal issues․ Continuous monitoring and updates to safety protocols are essential to uphold industry standards and foster a culture of safety within the organization․

Operator Responsibilities

Operators must wear safety harnesses, monitor equipment condition, and follow guidelines to ensure safe cherry picker operation, protecting themselves and others from potential hazards on site․

9․1 Ensuring Proper Use of Safety Harnesses

Operators must wear a full-body harness with a securely attached lanyard and anchor point․ Regular inspections ensure equipment functionality, preventing falls․ Proper use of safety harnesses is critical for operator protection during cherry picker operations, adhering to safety standards and manufacturer guidelines to minimize fall risks and ensure a safe working environment․ Compliance with these practices is non-negotiable for workplace safety․

9․2 Monitoring Equipment Condition

Regular monitoring of cherry picker condition is essential for safe operation․ Operators should inspect controls, tires, and hydraulic systems before each use․ Any damage or malfunction must be reported and addressed promptly․ Adhering to manufacturer guidelines ensures equipment reliability and compliance with safety standards, preventing potential accidents and downtime․

Cherry picker safety is paramount, requiring proper training, adherence to manufacturer guidelines, and regular inspections․ Ensuring PPE use, controlled movements, and situational awareness minimizes risks, promoting a safe working environment․

10․1 Recap of Key Safety Practices

Safe cherry picker operation requires consistent adherence to essential practices․ Always wear appropriate PPE, including a safety harness, and ensure weight limits are not exceeded․ Conduct thorough pre-use inspections and follow manufacturer guidelines․ Maintain controlled ascent and descent, avoid sudden movements, and stay alert to surroundings․ Proper training, situational awareness, and emergency preparedness are critical to minimizing risks and ensuring a safe working environment for all operators and nearby personnel․

10․2 Final Thoughts on Safe Cherry Picker Operation

Safe cherry picker operation is paramount to preventing accidents and ensuring efficiency․ Adherence to SOPs, proper training, and regular maintenance are essential․ Operators must stay vigilant, follow manufacturer guidelines, and use PPE correctly․ By prioritizing safety, workers can minimize risks and complete tasks effectively․ Remember, safety is a collective responsibility, requiring attention to detail and commitment from all involved to create a secure working environment․