The Cessna 182P maintenance manual is a comprehensive guide for servicing and maintaining the aircraft, ensuring safety and efficiency. It covers inspection procedures, repair processes, and essential compliance requirements, providing detailed instructions for both routine and complex maintenance tasks to keep the aircraft airworthy.

1.1 Overview of the Cessna 182P Aircraft

The Cessna 182P Skylane is a single-engine, four-seat aircraft renowned for its durability and versatility. Powered by a Continental IO-520-D engine producing 230 horsepower, it offers excellent performance and reliability. Its robust design makes it suitable for both personal and commercial use, including flight training and cargo transport. The aircraft features a Hartzell propeller and a forgiving flight characteristics, making it a popular choice among pilots. Its spacious cabin and payload capacity enhance its practicality, while its reputation for reliability ensures it remains a favorite in general aviation.

1.2 Importance of Regular Maintenance

Regular maintenance is critical to ensure the Cessna 182P remains airworthy and operates safely. It prevents mechanical failures, reduces repair costs, and extends the aircraft’s lifespan. Adhering to the maintenance manual’s guidelines ensures compliance with airworthiness directives and regulatory requirements. Proper maintenance also enhances performance, fuel efficiency, and overall safety, safeguarding both the aircraft and its occupants. Consistent upkeep allows early detection of potential issues, mitigating risks and ensuring reliability for continued flight operations.

1.3 Structure of the Maintenance Manual

The Cessna 182P maintenance manual is organized into sections for clarity and ease of use. It includes detailed inspection procedures, repair guidelines, and compliance requirements. The manual begins with an overview of the aircraft’s systems, followed by specific maintenance tasks. Sections cover daily inspections, 50-hour, and annual checks, ensuring a structured approach to upkeep. It also addresses airworthiness directives and record-keeping, providing a comprehensive framework for maintaining the aircraft’s safety and performance. This logical structure helps technicians and owners follow essential protocols efficiently.

Types of Maintenance Manuals for the Cessna 182P

The Cessna 182P maintenance manual includes the Pilot Operating Handbook (POH), Service Manual, and Maintenance Manual, each providing specific guidance for operation, repairs, and routine inspections.

2.1 Pilot Operating Handbook (POH)

The Pilot Operating Handbook (POH) for the Cessna 182P is a crucial document that provides detailed information on aircraft operation, performance, and safety procedures. It includes essential data on weight and balance, fuel management, and navigation systems. The POH also outlines normal and emergency operating procedures, ensuring pilots can handle various flight scenarios effectively. Additionally, it covers maintenance-related tasks that pilots can perform, such as pre-flight inspections and basic troubleshooting. This handbook is indispensable for both novice and experienced pilots, serving as a reference guide to maximize safety and efficiency during flight operations.

2.2 Service Manual

The Cessna 182P Service Manual provides detailed technical information for maintenance personnel, covering procedures for inspections, repairs, and part replacements. It includes troubleshooting guides, diagrams, and specifications to ensure compliance with airworthiness standards. The manual is tailored for professionals, offering in-depth guidance on systems such as engines, propellers, and avionics. Regular updates reflect the latest maintenance practices and regulatory requirements, making it an essential resource for keeping the aircraft in optimal condition and ensuring safety during operation and maintenance activities.

2.3 Maintenance Manual

The Cessna 182P Maintenance Manual offers step-by-step instructions for routine and complex maintenance tasks, ensuring compliance with airworthiness directives. It includes detailed inspection schedules, repair procedures, and part replacement guidelines. The manual emphasizes preventive maintenance, such as engine oil changes and propeller inspections, to maintain aircraft performance and safety. By following the manual’s recommendations, operators can extend the aircraft’s service life and reduce operational risks. It serves as a critical resource for mechanics and owners, providing clear, actionable guidance for all maintenance needs.

Preventive Maintenance Procedures

Preventive maintenance procedures for the Cessna 182P include regular inspections, routine tasks, and adherence to scheduled checks to ensure optimal performance and compliance with airworthiness standards.

3.1 Daily Inspections

Daily inspections for the Cessna 182P are crucial for ensuring aircraft airworthiness and safety. These checks include visual examinations of control surfaces, landing gear, and tires. Inspect the propeller for security and damage, and verify proper fluid levels. Check for signs of wear or damage on hinges, bolts, and fasteners. Ensure all control locks are removed and verify the functionality of flight controls. Review the aircraft’s logbooks for compliance with airworthiness directives and scheduled maintenance. Document all findings and address any issues promptly to maintain operational readiness.

3.2 50-Hour Inspections

The 50-hour inspection for the Cessna 182P involves detailed checks beyond daily routines. Inspect the engine oil filter and replace it as specified. Check spark plugs for wear and fouling, and clean or replace them as needed. Inspect the propeller for nicks, cracks, and erosion, and apply protective coatings if necessary. Lubricate moving parts and check the condition of engine mounts and baffles. Review the vacuum system, including filters and hoses, for leaks or blockages. Ensure compliance with all airworthiness directives and document findings thoroughly to maintain aircraft safety and performance.

3.3 Annual Inspections

The annual inspection is a comprehensive evaluation of the Cessna 182P, ensuring compliance with airworthiness standards. It includes a detailed examination of the engine, propeller, and avionics systems. Inspectors check for wear on moving parts, corrosion, and any signs of damage. The landing gear, brakes, and tires are thoroughly evaluated, and fluid levels are checked. Additionally, the electrical system, fuel lines, and control surfaces are inspected for proper function and integrity. All findings are documented, and any necessary repairs or replacements are addressed to ensure the aircraft remains safe and airworthy.

Common Maintenance Tasks

Common maintenance tasks for the Cessna 182P include engine oil changes, propeller inspections, and landing gear maintenance. These routines ensure optimal performance and safety.

4.1 Engine Oil Change

Regular engine oil changes are crucial for the longevity and performance of the Cessna 182P’s engine. The process involves draining the old oil, replacing the oil filter, and refilling with the recommended type and quantity of oil. Proper disposal of used oil and filters is essential to comply with environmental regulations. The maintenance manual provides detailed steps, including torque specifications for the oil drain plug and filter. Additionally, it emphasizes the importance of using high-quality materials to prevent engine damage. This routine task is typically performed every 50 hours of flight time or as specified in the manual.

4.2 Propeller Inspection

Regular propeller inspection is essential for ensuring the Cessna 182P’s safety and performance. The process involves visually examining the propeller blades for cracks, nicks, and corrosion. Additionally, the hub and bolts should be checked for looseness or damage. The maintenance manual recommends inspections at specified intervals, typically every 100 hours of flight time. Proper cleaning and lubrication of moving parts are also critical. Any damage or wear must be addressed promptly to prevent vibration issues or reduced efficiency. Adhering to the manual’s guidelines ensures optimal propeller function and contributes to overall aircraft reliability and safety.

4.3 Landing Gear Maintenance

Landing gear maintenance for the Cessna 182P involves thorough inspection and lubrication of components. The manual specifies checking for hydraulic fluid leaks, worn-out bushings, and proper tire pressure. Wheel bearings must be cleaned and repacked with grease annually. Brake pads should be inspected for wear, and replaced if thickness falls below minimum specifications. Additionally, the landing gear strut should be serviced to maintain proper compression and extension. Regular maintenance ensures smooth landings, prevents premature wear, and maintains the structural integrity of the landing gear system, crucial for safe operations.

Troubleshooting and Repair

Troubleshooting involves identifying issues like mechanical malfunctions or system failures. Repairs require adherence to manual guidelines, specialized tools, and compliance with airworthiness directives to ensure safety and reliability.

5.1 Identifying Common Issues

Common issues in the Cessna 182P include wing incidence misalignment, flap asymmetry, and engine cooling system malfunctions. Pilots and mechanics should inspect for cracks in the stabilizer, worn hinge bearings, and failed fasteners. Regular visual inspections of the propeller, landing gear, and control surfaces are crucial. Troubleshooting also involves monitoring engine performance, oil leaks, and unusual vibrations. Proper identification of these issues ensures timely repairs, preventing minor problems from escalating. Always refer to the maintenance manual for specific diagnostic procedures and guidelines to maintain airworthiness and operational safety.

5.2 Repair Procedures

Repair procedures for the Cessna 182P involve systematic steps to address identified issues. Start by consulting the maintenance manual for specific guidance. For structural repairs, non-destructive testing (NDT) may be required to detect hidden damage. Replace damaged or worn parts with OEM or FAA-approved components. Ensure all fasteners are tightened to specified torque values. Lubricate moving parts as recommended. Complex repairs, such as engine overhauls, should be performed by certified mechanics. Always document repairs in the aircraft logbook and ensure compliance with airworthiness directives. Post-repair inspections and functional tests are mandatory to confirm the aircraft’s safe operation.

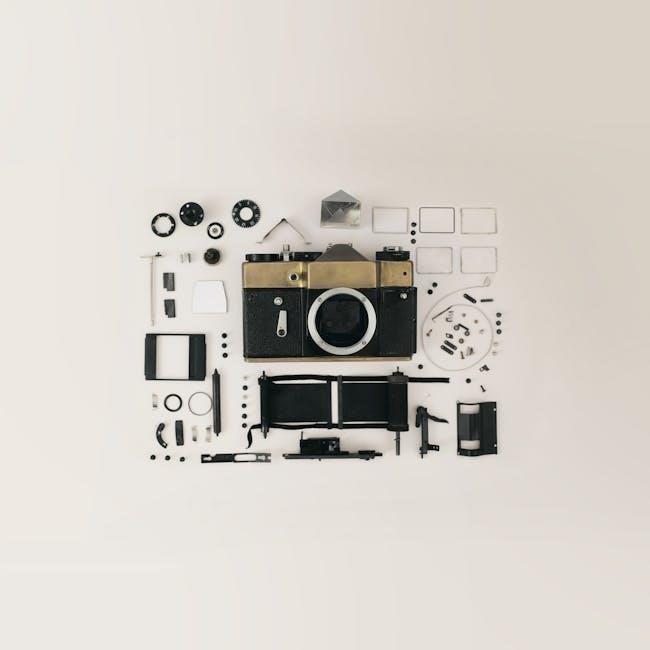

5.3 Tools and Equipment Needed

Essential tools for maintaining the Cessna 182P include wrenches, screwdrivers, pliers, and torque wrenches. Specialized tools like micrometers and rivet guns are required for specific tasks. Aviation-specific equipment, such as drain kits for oil and hydraulic systems, is also necessary. Ensure all tools meet aviation standards for precision and durability. Referencing the maintenance manual is crucial for identifying the exact tools needed for each procedure. Proper equipment ensures compliance with safety standards and efficient completion of repairs. Always use high-quality tools to maintain the aircraft’s airworthiness and performance.

Airworthiness Directives and Compliance

The Cessna 182P manual provides inspection procedures and AD guidance, ensuring compliance with mandates stemming from fleet incidents, such as NDT regimes or component replacements for safety and airworthiness.

6.1 Understanding Airworthiness Directives

Airworthiness directives (ADs) are regulatory requirements issued to ensure the continued safety of aircraft. For the Cessna 182P, ADs often stem from recurring issues identified across the fleet, such as structural concerns or system malfunctions. These directives mandate specific actions like non-destructive testing (NDT), component reinforcement, or replacement. Compliance with ADs is critical to maintaining airworthiness and preventing potential incidents. The Cessna 182P maintenance manual outlines these directives, providing clear guidance on inspections and necessary modifications to ensure the aircraft remains safe and operational.

6.2 Compliance Requirements

Compliance with airworthiness directives and maintenance standards is mandatory for the Cessna 182P. Operators must adhere to FAA regulations and manufacturer guidelines, ensuring all inspections, repairs, and modifications are documented. Regular inspections, such as annual and 100-hour checks, are critical to maintaining compliance. Failure to meet these requirements can result in the aircraft being deemed unairworthy. Proper record-keeping and adherence to approved data are essential to demonstrate compliance and ensure the aircraft’s safety and reliability for continued operation.

6.3 Record-Keeping and Documentation

Accurate and detailed record-keeping is essential for maintaining the Cessna 182P’s airworthiness. All maintenance activities, inspections, and repairs must be documented in the aircraft’s maintenance logs. The Pilot Operating Handbook (POH) and service manuals provide specific guidance on required entries. Compliance with FAA regulations mandates that all records, including inspection dates and completed repairs, are up-to-date and accessible. Proper documentation ensures traceability of maintenance actions and is critical for proving adherence to airworthiness standards during inspections. Inadequate or missing records can lead to operational restrictions or grounding of the aircraft.